* Hohenstein and Centa-Star develop special bedding for dust mite allergy sufferers

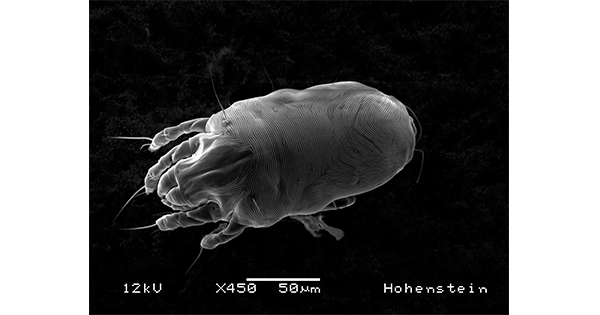

Between 10 and 15% of the population are allergic to dust mites, asthma is one of the most common illnesses in the world – and the number of people affected is rising year after year. Millions of Germans are familiar with year-round runny noses in the mornings, sneezing attacks, itchy eyes and severe reactions that may include shortage of breath. The symptoms often have a very detrimental effect on their everyday lives, so taking preventive measures is important, from the point of view of both the economy and healthcare policy. For allergy sufferers, the most important preventive measure they can take is to keep allergens away from their respiratory organs – especially in the bedroom.

One of the main areas of work at the Hohenstein Group’s William Küster Institute for Hygiene, Environment and Medicine (WKI) is researching the compatibility of textiles for users, and this includes the management of allergens. That is why Hohenstein spotted the potential of textile-based allergy prevention at an early stage and worked closely with the industry to find a solution: over months of fundamental research, and multiple optimization stages, Hohenstein developed a negatively charged textile finish which attracts the positively-charged allergens like a magnet.

Now, in partnership with the Stuttgart-based bedding manufacturer Centa-Star, Hohenstein has turned this textile finish into a marketable product: AllergoProtect – a trio of products consisting of mattress topper, duvet and pillow, which retain over 99.5% of the allergens inside the filling and the cover, even under great mechanical strain, for example when the bedding is shaken. This means the allergens are not breathed in and no longer cause allergic reactions. During washing, the allergens bound to the fibers are removed from the filling of the bedding, and the physical binding function of the textile is regenerated – and remains fully effective even after 10 washes at 60°C in a domestic washing machine using heavyduty detergent followed by tumble drying.

Now, in partnership with the Stuttgart-based bedding manufacturer Centa-Star, Hohenstein has turned this textile finish into a marketable product: AllergoProtect – a trio of products consisting of mattress topper, duvet and pillow, which retain over 99.5% of the allergens inside the filling and the cover, even under great mechanical strain, for example when the bedding is shaken. This means the allergens are not breathed in and no longer cause allergic reactions. During washing, the allergens bound to the fibers are removed from the filling of the bedding, and the physical binding function of the textile is regenerated – and remains fully effective even after 10 washes at 60°C in a domestic washing machine using heavyduty detergent followed by tumble drying.

Hohenstein also helps with market positioning, thanks to its quality label and regular quality control of the materials that are used. AllergoProtect is certified under the STANDARD 100 by OEKO-TEX Class I – the Standard 100 product class that has the strictest specifications for human ecology.

The endurance testing for AllergoProtect was carried out by the European Centre for Allergy Research Foundation and it has been awarded the ECARF Seal of Quality. In trials with volunteers, the effectiveness of AllergoProtect was impressively demonstrated. Now AllergoProtect is protected by a registered patent and after just a short time is already in great demand in the retail business. So AllergoProtect is just one more example of the success that proves the Hohenstein Institute to be a reliable research partner for industry.

Three questions for Dr. Hammer, from Hohenstein, and Thomas Müller, from Centa-Star:

1. How did the idea come about of using a special textile finish to bind the allergens to the bedding so that allergy sufferers are protected from them?

Dr. Hammer, Hohenstein: The idea was the result of looking at an entirely different

question: at the WKI we had been closely studying the question of how odor molecules (such as sweat odor) could be bound to fibres and how they could then be released from the fibers again. Precisely this binding of the molecules to the fibers is an effective way of keeping the odors away from your nose. So we hit upon the idea of applying the same principle to allergens.

• Thomas Müller, Centa-Star: The researchers at the Hohenstein Institute found out that allergens have a positive charge. So we jointly came up with the idea of developing a product for allergy sufferers which would make use of the physical principle of magnetic attraction – instead of the heavy-duty encasings and biocides that had been used until then.

2. How did the partnership with Centa-Star come about?

Dr. Hammer, Hohenstein: Centa-Star and Hohenstein have been working together for a long time. So Centa-Star is a member of our Scientific Board, a committee made up of representatives from industry and associations which advises Hohenstein’s researchers on converting research results into industrial applications. After all, the best research results are of little use if they have no practical significance. Then when we were chatting, we decided to work together on this project.

3. What were the main challenges when you were developing AllergoProtect?

Thomas Müller, Centa-Star: The binding of the allergens needed to be very effective. But at the same time, the effect had to be reversible, because it had to be possible to remove the allergens by washing in the washing machine. And of course the materials that were used needed, themselves, to be skin-friendly and non-allergenic and proven in countless tests and trials with volunteers. At the end of this long process, the products were successfully awarded the Seal of Quality and certified under Standard 100 by OEKO-TEX. Last but not least, marketing this new product in an easily understandable way was also quite a challenge.